Styrofoam, ubiquitous in our modern lives, presents a significant challenge to environmental sustainability. This guide delves into the intricacies of Styrofoam recycling, from its production and usage to practical tips for home and community-level recycling initiatives. We’ll examine the misconceptions surrounding its recyclability and explore effective methods, while highlighting the environmental and economic impact of these practices.

Understanding the different types of Styrofoam and their respective recycling statuses is crucial. This guide will provide a comprehensive comparison, outlining the challenges and opportunities associated with each recycling method. We’ll explore various processes, from household initiatives to industrial-scale recycling, highlighting successful programs and the steps involved in each.

Introduction to Styrofoam Recycling

Styrofoam, a ubiquitous material in packaging and various consumer goods, is commonly perceived as a plastic. However, its composition and properties make it significantly different from many other plastics, leading to complexities in its recycling process. This section will delve into the nature of Styrofoam, the common misconceptions surrounding its recyclability, and the broader environmental impact of its widespread use.Styrofoam, predominantly composed of expanded polystyrene, is a lightweight, porous material, often mistaken for a type of plastic due to its widespread use in plastic-like applications.

A crucial misconception is that Styrofoam is recyclable in the same manner as other plastics. In actuality, the current recycling infrastructure for Styrofoam is limited and largely depends on specialized facilities.

Types of Styrofoam

While often referred to as a single material, Styrofoam can come in different forms, varying in density and intended use. These variations can impact the potential for recycling. However, the fundamental composition remains the same, meaning that the core recycling challenges remain consistent. For example, the density of Styrofoam used in insulation differs from that used in packaging.

The varying degrees of expansion and density don’t fundamentally alter the material’s core properties that hinder its recyclability.

Global Impact of Styrofoam Waste

The widespread use of Styrofoam has resulted in a significant global accumulation of waste. This waste poses a threat to ecosystems and contributes to environmental pollution. The persistent nature of Styrofoam, which can take hundreds of years to decompose, means that it accumulates in landfills and natural environments. The global impact is evident in the increasing presence of Styrofoam debris in oceans and other natural habitats.

For instance, the Great Pacific Garbage Patch contains substantial amounts of Styrofoam, impacting marine life.

History of Styrofoam Production and Usage

Styrofoam’s production and use have significantly evolved since its invention. Initially developed as a lightweight insulating material, it quickly gained popularity for its versatility in packaging. The material’s ease of shaping and lightweight nature made it a popular choice for packaging various products. The increased availability of readily shaped, lightweight materials led to widespread adoption in consumer goods.

Over time, this prevalence resulted in a significant rise in waste generation.

Comparison of Plastic Types and Recycling Status

| Plastic Type | Recyclability | Common Uses | Recycling Symbol |

|---|---|---|---|

| Styrofoam (Expanded Polystyrene) | Limited; typically not accepted in curbside programs. Requires specialized facilities. | Packaging, insulation, disposable cups, and other consumer goods. | Generally, no standard recycling symbol. |

| Polyethylene Terephthalate (PET) | Generally recyclable; often accepted in curbside programs. | Bottles, containers, and food packaging. | 1 |

| High-Density Polyethylene (HDPE) | Generally recyclable; often accepted in curbside programs. | Containers, bottles, and pipes. | 2 |

| Polyvinyl Chloride (PVC) | Limited recyclability; often not accepted in curbside programs. | Pipes, flooring, and packaging. | 3 |

Methods for Styrofoam Recycling

Styrofoam, despite its widespread use, presents a significant recycling challenge. Its unique composition and widespread presence in various products make traditional recycling methods less effective. This section details the diverse approaches to Styrofoam recycling, evaluating their effectiveness, and highlighting the associated challenges.Different methods for Styrofoam recycling are available, each with its own set of advantages and disadvantages. These approaches range from simple, home-based techniques to sophisticated industrial processes.

Understanding these methods allows individuals and organizations to choose the most appropriate and effective approach for their specific needs.

Industrial Recycling Methods

Industrial recycling processes for Styrofoam typically involve specialized equipment and facilities. These methods aim to recover the raw materials from Styrofoam for reuse in manufacturing new products.One significant method is mechanical recycling. This involves grinding the Styrofoam into small pieces and then processing it further to separate the material. The separated materials can then be used in various applications.

Mechanical recycling is often used for large volumes of Styrofoam waste, such as those generated by industrial facilities or large-scale events.Another method is chemical recycling. This approach uses chemical processes to break down Styrofoam into its basic components. This method can recover valuable monomers, which can then be used to create new products. Chemical recycling is often more complex and costly than mechanical recycling, but it has the potential to recover more material and create a more environmentally friendly process.

One example of chemical recycling is using supercritical carbon dioxide to break down Styrofoam.

Challenges Associated with Industrial Recycling

Significant challenges hinder the widespread adoption of industrial recycling methods for Styrofoam. The high cost of specialized equipment and facilities often limits accessibility for smaller recycling programs. Furthermore, the availability of suitable processing facilities may be limited, creating logistical challenges. The process of chemical recycling, for instance, often involves hazardous chemicals and specialized processes, which raise safety and environmental concerns.

Home Recycling Methods

Home recycling of Styrofoam often focuses on reducing waste generation rather than complete recycling.This often involves reducing the consumption of Styrofoam products and properly disposing of Styrofoam packaging to reduce landfill burden.

Steps for Home Styrofoam Recycling

| Step | Action | Materials Needed | Important Considerations |

|---|---|---|---|

| 1 | Identify and separate Styrofoam packaging from other recyclables. | None | Ensure all other recyclable materials are separated. |

| 2 | If possible, compress the Styrofoam pieces to reduce volume. | Heavy-duty plastic bags or boxes | Properly handle and dispose of Styrofoam to avoid injuries. |

| 3 | Check local recycling guidelines to see if your community accepts Styrofoam. | None | Not all municipalities have Styrofoam recycling programs. |

| 4 | If your community does not have a Styrofoam recycling program, consider proper disposal methods. | None | Disposal should be in accordance with local regulations. |

Materials and Tools Needed

Recycling Styrofoam effectively requires the right materials and tools, tailored to the specific recycling process. Careful selection and proper handling are crucial for safety and efficiency. This section Artikels the necessary resources, safety precautions, cost considerations, and availability for both small-scale and industrial Styrofoam recycling projects.

Materials for Styrofoam Recycling

The fundamental material for Styrofoam recycling is, of course, the Styrofoam itself. Different types of Styrofoam require different approaches. For instance, expanded polystyrene (EPS), commonly used in packaging, necessitates different methods than extruded polystyrene (XPS), used in insulation. Beyond the raw material, specialized tools and chemicals are often necessary.

Tools for Styrofoam Recycling

The specific tools needed vary significantly depending on the scale and method of recycling. Small-scale recycling might involve simple tools, while industrial recycling demands specialized equipment. Tools like shredders, grinders, and specialized conveyors are essential for large-scale processing, while smaller projects might use hammers, chisels, or even handsaws for disassembly and preparation. It is critical to choose the appropriate tools based on the type of Styrofoam being recycled and the desired outcome.

Safety Precautions for Styrofoam Recycling

Safety is paramount throughout the Styrofoam recycling process. Working with Styrofoam, especially in industrial settings, carries inherent risks. Personal protective equipment (PPE) like safety glasses, gloves, and respirators is crucial for mitigating potential hazards. Handling sharp tools, operating machinery, and working with chemicals all necessitate adherence to strict safety protocols. The proper ventilation and storage of chemicals used in the recycling process are also vital safety considerations.

Cost Considerations for Materials and Tools

The cost of materials and tools varies significantly based on the scale and complexity of the project. Simple hand tools for small-scale recycling will have a lower cost compared to industrial-grade shredders and grinders. The price of raw Styrofoam material, depending on the type, also fluctuates based on market conditions. It is recommended to factor in the cost of maintenance, repairs, and replacement of tools over the long term.

Availability of Materials and Tools

The availability of materials and tools depends heavily on location and scale. Small-scale recyclers might find necessary materials readily available at hardware stores, while industrial recyclers will need to procure equipment from specialized suppliers. The availability of recycled Styrofoam itself depends on the local recycling infrastructure and the demand for recycled materials.

Table of Industrial Recycling Tools

| Tool | Description | Use | Safety Precautions |

|---|---|---|---|

| Industrial Shredder | Large machine for reducing Styrofoam into smaller pieces. | Reduces large pieces of Styrofoam for easier processing. | Wear appropriate PPE (safety glasses, gloves, hearing protection). Ensure proper maintenance and servicing of the machine. Operate only with proper training. |

| Grinder | Machine for grinding Styrofoam into fine particles. | Reduces Styrofoam to powder or small granules. | Ensure adequate ventilation and use of respirators, as fine dust can be hazardous. |

| Conveyor Belt System | System for transporting Styrofoam pieces between different stages of the recycling process. | Efficiently transports Styrofoam to various processing stations. | Ensure proper belt tension and maintenance to prevent accidents. Use safety mechanisms for secure operation. |

| Chemical Dissolver (for specific types) | Equipment used for dissolving Styrofoam using specific chemicals. | Dissolves Styrofoam for material recovery. | Use in a well-ventilated area. Adhere to specific chemical handling procedures. Wear appropriate protective gear (gloves, respirators, safety glasses). |

Community and Environmental Impact

Styrofoam recycling, while often overlooked, holds significant potential for positive environmental and community impacts. By diverting this material from landfills, we can reduce its contribution to pollution and resource depletion. Effective recycling programs can foster a sense of shared responsibility for environmental stewardship within communities, creating a more sustainable future.

Environmental Benefits of Styrofoam Recycling

Recycling Styrofoam reduces the strain on natural resources. Manufacturing new products from raw materials requires substantial energy and often involves the extraction of valuable resources. Recycling, on the other hand, conserves these resources and minimizes the need for new extraction. Furthermore, diverting Styrofoam from landfills reduces the release of methane, a potent greenhouse gas, which accelerates climate change.

This contributes to a healthier environment for present and future generations.

Community-Level Impact of Styrofoam Recycling Programs

Recycling programs can create opportunities for community engagement and education. Residents can actively participate in the process, fostering a sense of collective responsibility. Such programs can also generate economic benefits for the community by creating jobs in recycling facilities and related industries. Successful community recycling programs demonstrate the collective power of individual actions in making a positive impact on the environment.

Economic Impact of Styrofoam Recycling

Recycling Styrofoam can lead to cost savings for businesses and municipalities. The reduction in waste disposal costs is a direct economic benefit. Furthermore, the development of new products from recycled Styrofoam can create new markets and stimulate economic growth. Examples of economic benefits include the creation of jobs in recycling facilities and the potential for the development of innovative recycling technologies.

Role of Government Regulations and Incentives

Government regulations and incentives play a crucial role in encouraging Styrofoam recycling. Regulations can mandate specific recycling targets or impose penalties for improper disposal. Incentives, such as tax breaks for businesses that implement recycling programs, can further motivate participation. Effective regulations and incentives drive significant improvements in recycling rates, contributing to broader environmental and economic benefits.

Comparison of Recycling Rates Across Different Communities

Recycling rates for Styrofoam vary significantly across communities, depending on factors such as public awareness, the availability of recycling infrastructure, and government regulations. Communities with strong public awareness campaigns and well-established recycling programs often demonstrate higher Styrofoam recycling rates. Communities with robust government support and infrastructure are more likely to achieve higher rates compared to communities with limited resources.

Correlation Between Styrofoam Recycling and Waste Reduction

A direct correlation exists between Styrofoam recycling and waste reduction. By diverting Styrofoam from landfills, we directly reduce the volume of waste needing disposal. This leads to a reduction in the environmental impact of waste management. Additionally, it frees up space in landfills for other waste materials, contributing to more sustainable waste management practices.

Converting Recycled Styrofoam into New Products

The process of converting recycled Styrofoam into new products involves several steps. First, the Styrofoam is collected and sorted. Then, it undergoes a cleaning and processing stage, typically involving shredding and melting. After this, the processed material can be molded into new products, such as insulation, packaging materials, and even composite building materials. The creation of these new products from recycled materials conserves resources and reduces waste.

Practical Tips for Recycling Styrofoam

Recycling styrofoam effectively requires a multi-faceted approach that goes beyond simply placing it in a recycling bin. This section provides practical guidance to ensure styrofoam is recycled correctly, minimizing contamination and maximizing its potential for reuse.

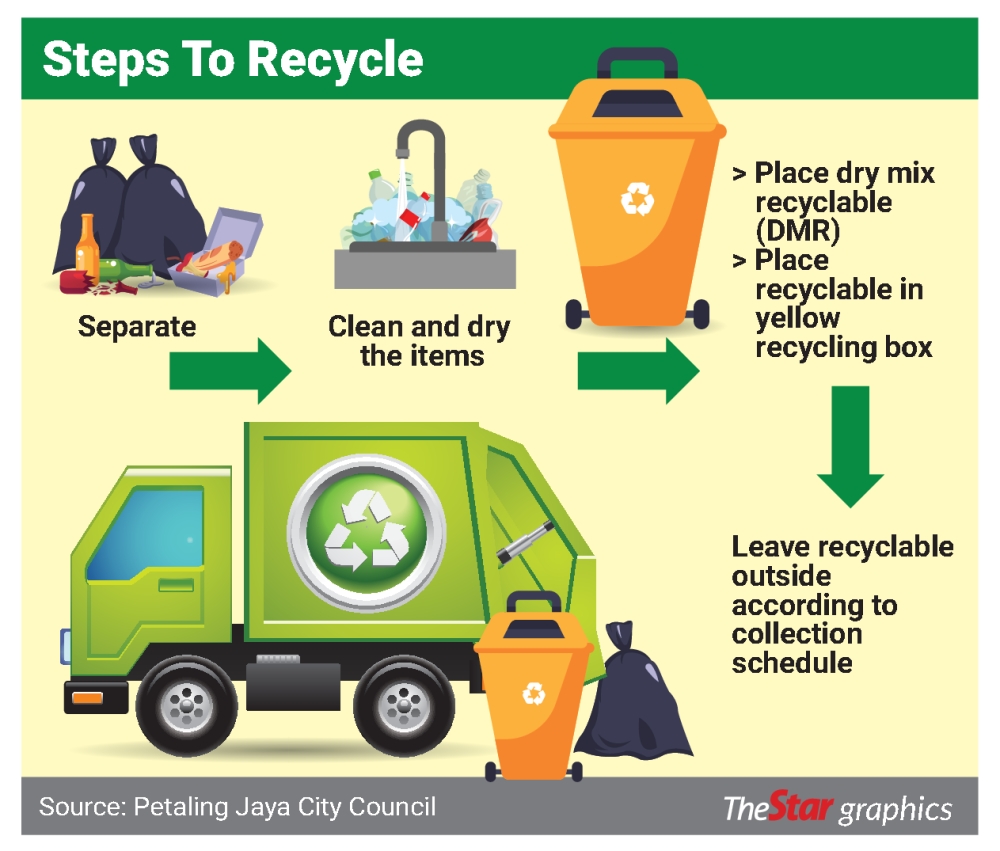

Simple Steps for Styrofoam Recycling

Proper styrofoam recycling involves more than just tossing it in a bin. Understanding the nuances of your local recycling guidelines is crucial for successful participation. Follow these steps for optimal styrofoam recycling:

- Cleanliness is Key: Thoroughly clean styrofoam containers to remove any food residue, labels, or other contaminants. This crucial step prevents contamination of other recyclables.

- Size Matters: Break down large pieces of styrofoam into smaller, manageable pieces to improve handling and sorting efficiency. This ensures styrofoam doesn’t take up excessive space in the recycling process.

- Proper Disposal: Ensure your local recycling guidelines are followed. Some municipalities require styrofoam to be collected in separate containers. Always verify these guidelines with your local recycling facility.

Importance of Proper Disposal

Proper styrofoam disposal is vital for maintaining the integrity of the recycling stream. Contaminated styrofoam can negatively impact the quality of recycled materials and lead to processing difficulties. This is essential for maximizing recycling efficiency.

- Preventing Contamination: Removing food debris and other foreign materials before disposal ensures that styrofoam does not contaminate other recyclable materials during the recycling process. This prevents costly issues in the recycling plant.

- Maintaining Quality: Proper disposal contributes to the overall quality of the recycled materials, leading to better end products and reducing the need for additional resources in the recycling process.

- Facilitating Recycling: By adhering to proper disposal procedures, individuals contribute to a smoother recycling process, enabling recycling facilities to process materials more efficiently. This contributes to a more sustainable and effective recycling system.

Local Recycling Guidelines

Local recycling guidelines vary. Contact your local waste management authority or municipality for specific instructions regarding styrofoam recycling. This is vital for understanding local regulations.

| City/Region | Styrofoam Recycling Guidelines |

|---|---|

| Example City A | Styrofoam must be cleaned and shredded before disposal. It should be placed in a separate container for recycling. |

| Example City B | Styrofoam is not accepted for recycling at municipal facilities. Contact a private recycling company for disposal options. |

Handling Contaminated Styrofoam

Contaminated styrofoam presents a challenge to recycling facilities. Understanding how to handle contaminated styrofoam is essential for successful recycling.

- Separate Disposal: If contamination is minimal, it may be possible to clean the styrofoam and recycle it separately. If contamination is significant, separate disposal is recommended.

- Proper Cleaning: Employ appropriate cleaning methods to remove any contamination. This could involve using soap and water or specialized cleaning solutions.

- Contact Local Authorities: Contact your local recycling center for specific instructions on handling contaminated styrofoam, especially for items that are significantly contaminated. This is crucial for compliance and proper disposal.

Sorting Styrofoam Before Recycling

Proper sorting is crucial for maximizing the effectiveness of styrofoam recycling. It prevents contamination and allows for efficient processing.

- Separation by Type: Sort styrofoam according to its type, e.g., food containers, packaging materials. Different types of styrofoam may have varying recycling guidelines.

- Removal of Contamination: Carefully remove any non-styrofoam materials, such as labels or food remnants, to prevent contamination of the recycling stream.

- Size Reduction: Break down large pieces into smaller ones to improve sorting efficiency and minimize space requirements.

Simple Solutions for Common Recycling Problems

Troubleshooting recycling issues can be easily resolved with a few simple steps.

- Incorrect Container: Ensure the styrofoam is placed in the designated container for recycling. Check local guidelines for proper placement.

- Contamination: Remove any contaminants from the styrofoam, and if possible, clean it before recycling.

- Incorrect Sorting: Ensure styrofoam is sorted properly. Refer to local guidelines for proper sorting methods.

Flowchart for Contaminated or Mixed Recycling

A flowchart can guide individuals through the process of handling contaminated or mixed recycling materials:[Insert flowchart image here. The flowchart should depict steps such as identifying contamination, cleaning the item, and contacting local authorities for specific disposal instructions. ]

Epilogue

In conclusion, recycling Styrofoam is achievable and vital for environmental protection. By understanding the different methods, necessary materials, and community-level impact, individuals can contribute to a more sustainable future. This guide offers a practical approach, equipping readers with the knowledge and tools to effectively recycle Styrofoam and minimize its environmental footprint. From the simple steps for home recycling to the complexities of industrial processes, we have provided a comprehensive overview.